Product center

◆Equipment introduction:

The fine grid adopts the "reverse rotation filtration method" to become the leader in solid-liquid separation machinery with excellent solid-liquid separation performance, stable operation, not easy to block, and automatic inspection.

When the wastewater enters the plum net, the "reverse shear force" effect occurs between the grid and the water, which increases the relative flow rate of the filtrate and the grid to achieve better separation. The filtrate flows out from the grid gap and stays in the grid. The filter residue is pushed by the tongue residue plate to the residue discharge port and discharged.

The V-shaped carrier surface mold grid is spirally wound on the grid bone. The wedge and the grid bone are automatically arranged and connected. High-frequency resistance welding is used to connect the city to ensure that the welding is firm.

◆Technical features:

95% of the solid slag larger than the grid gap and 50% of the solid slag equivalent to the grid gap can be intercepted. V-shaped cross-section wedge-shaped grid gap is from 0.2mm to 6mm to meet the needs of different processes. The carburizing process is added to the grid surface to achieve high hardness and prolong the service life of the equipment. The sturdy grid bone design reduces the stress concentration of the V-shaped wedge-shaped grid, which is more in line with the treatment of high-concentration materials.

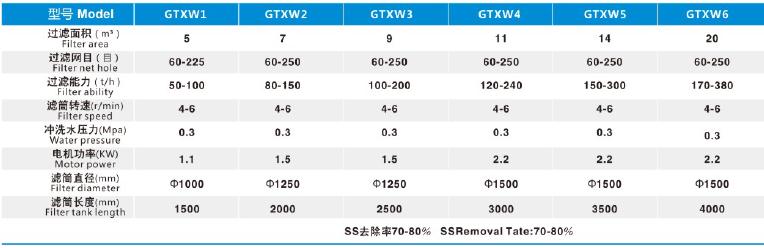

◆Equipment parameters: