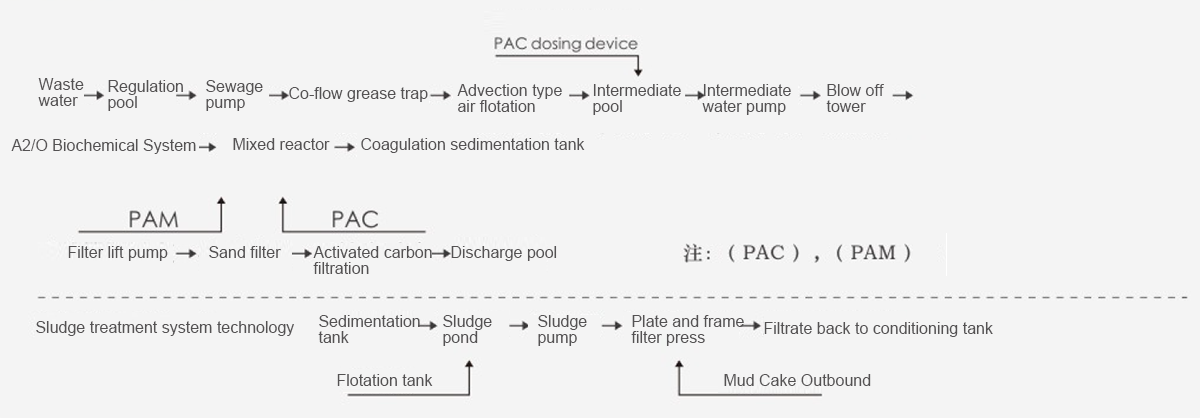

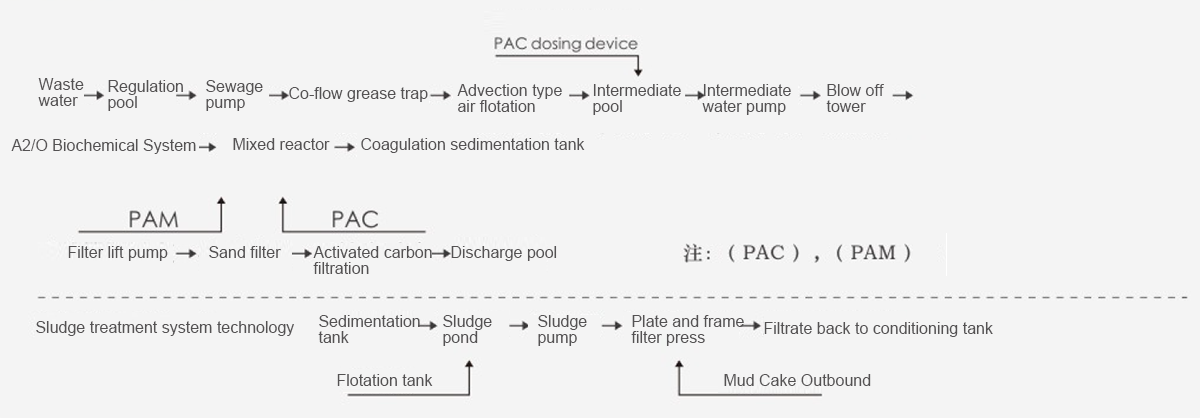

Coking water pollutant treatment process

◆Process introduction

Coking wastewater is wastewater produced during the high-temperature carbonization of raw coal, gas purification, and chemical product refining. There are three main sources:-Residual ammonia, which is wastewater produced during coal carbonization and gas cooling. Its water volume accounts for the total coking process. More than half of the amount is the main source of coking wastewater; the second is the waste water produced in the gas purification process, such as the final cooling of the gas and the crude benzene separation water, etc.; the third is produced in the refining process of tar and crude oil and other occasions. Wastewater. Coking wastewater is industrial wastewater containing a large amount of refractory organic pollutants. Its composition is complex and contains a large amount of harmful substances such as phenol, cyanide, benzene, ammonia, etc. The coking wastewater discharged in excess of the standard causes serious environmental pollution.

In China, the coking wastewater is generally treated by the physicochemical + biochemical process. First, the oil particles are removed through the grease trap and air flotation, and then the phenol, ammonia and cyanogen sulfide are removed through the stripping tower, and then through the A2/O The biochemical method carries out denitrification treatment, and the biochemical effluent enters the coagulation reactor to further remove COD and oil. Remove phenols and COD through secondary filtration to ensure that the effluent of the system meets the discharge standards.