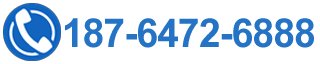

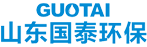

Printing and dyeing wastewater treatment process

◆Process introduction

The waste water is collected by the pipeline and enters the waste water treatment station by itself. The large floating debris in the waste water is removed by the mechanical grille, and then enters the regulating tank by itself. After homogenization and uniformity, the waste water is lifted to the air floatation machine by the lifting pump. First, flocculate with the added flocculant to form a larger "alum" under the action of the aerator. The effluent flows into the anaerobic reaction tank for anaerobic reaction. During the anaerobic reaction, the macromolecular pollutants in the wastewater undergo a process of fragmentation and chain scission, which changes its performance. Create conditions for the subsequent aerobic reaction process. The pretreated wastewater flows into the decomposition oxidation tank for aerobic treatment. The oxygenated mixture immerses all the fillers and flows through the fillers at a certain flow rate due to the fillers. The surface is covered with biofilms, and the wastewater is in extensive contact with the biofilms. Under the metabolism of microorganisms on the biofilms, the organic matter in the wastewater is effectively removed and the wastewater is purified. The compressed air produced by the Roots blower enters the tank through the pipeline, and supplies the oxygen required for the respiration of microorganisms through aeration, and plays a role of stirring and mixing. After the reaction, the mixed liquid flows into the sedimentation tank for mud and water separation and then flows to the intermediate tank. Part of the color is removed by secondary filtration, and then the effluent is disinfected and discharged up to the standard. The sludge produced by precipitation is returned to the anaerobic reaction tank and contact oxidation tank through the return sludge pump to supplement the lost biological sludge. The surplus sludge and the sludge from the air flotation machine are discharged to the sludge tank, and the sludge dewatering treatment is carried out with a filter press. The filtrate is returned to the anaerobic reaction tank. Mud cakes are shipped out.