Product center

◆Product description:

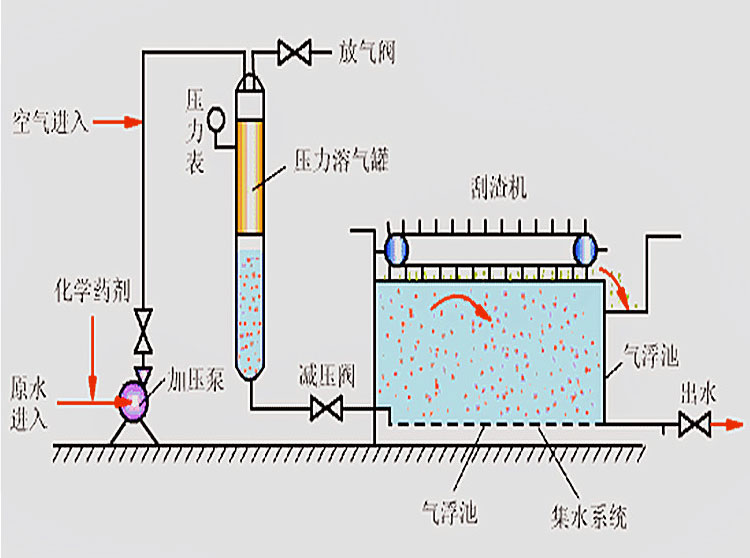

Advection type air flotation machine is mainly used for solid-liquid or liquid-liquid separation. Through the dissolved air and release system, a large number of fine bubbles are generated in the water, making them adhere to the solid or liquid particles in the wastewater with a density close to that of water, resulting in a state where the overall density is less than water, and relying on buoyancy to make it rise to the water surface. To achieve the purpose of solid-liquid or liquid-liquid separation.

◆Structure

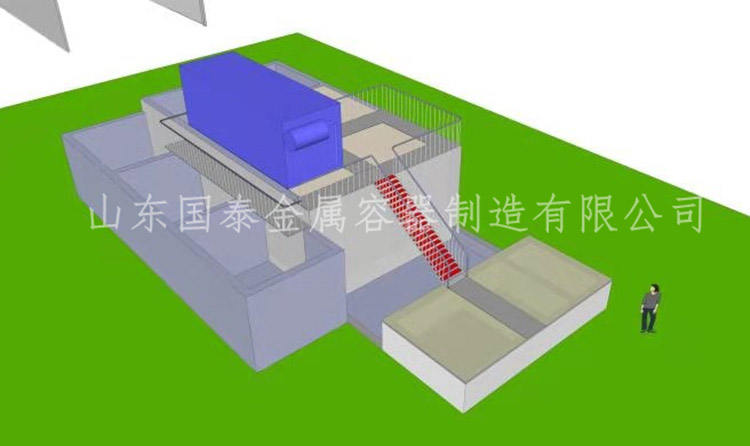

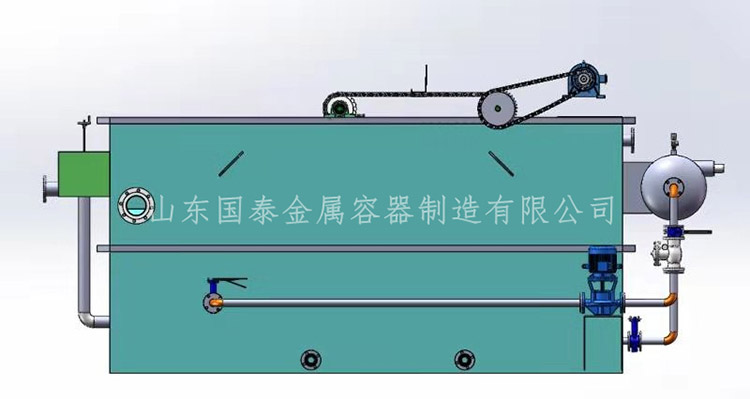

The main body of the equipment is composed of a high-pressure dissolved gas system, a low-pressure release system, a reaction chamber, a contact chamber, a separation chamber, a sedimentation cone (some models), a water collection and a liquid level balance control device, and a dosing (semi-automatic) according to the water quantity and quality Or fully automatic) system.

1. The air flotation system integrates water inlet, flocculation, separation, water collection, and water outlet. Similar to traditional air flotation equipment, it is equipped with a steady flow chamber and a dissolved air release chamber, which makes the processing performance more stable and the effect is more superior. The transformation of traditional equipment is particularly suitable.

2. Stabilization chamber: The raw water reacted by the folding plate has a high flow rate. If it directly contacts the dissolved gas water, it will dissipate the tiny bubbles and affect the effect of bubbles adhering to the flocs, thereby reducing the efficiency of air flotation treatment. If the steady flow chamber is added , So that the kinetic energy of the turbulent raw water is consumed, and it enters the dissolved gas water release chamber at a uniform speed, thereby effectively ensuring the removal effect.

3. Dissolved gas release chamber: The dissolved gas release chamber and the separation chamber are in a tank. Dissolved air water adheres to the flocculated raw water here, slowly rises, and enters the air flotation separation chamber to ensure the contact space and time between the floccules and the tiny bubbles, so that the release rate of the dissolved air water reaches 80-100 %.

◆Working principle:

Pollutants in sewage are divided into dissolved organic matter and insoluble matter (ie SS). Under certain conditions, dissolved organic matter can be transformed into insoluble degradable matter. One of the methods of sewage treatment is to add coagulant and flocculation. The agent transfers most of the soluble organic matter into insoluble matter, and then removes all or most of the insoluble matter (ie SS) to purify sewage. The main method of removing SS is to use air flotation. .

The sewage after the dosing reaction enters the air flotation mixing zone, mixes and contacts with the released dissolved air water, so that the flocs adhere to the fine bubbles, and then enter the air flotation zone. The flocs float to the water surface under the action of air buoyancy to form scum. After the clean water in the lower layer flows to the clean water tank through the water collector, a part of it flows back for use as dissolved air, and the remaining clean water flows out through the overflow. After the scum on the water surface of the air floatation tank has accumulated to a certain thickness, it is scraped into the air floatation sludge tank by the foam scraper and discharged.

◆Equipment parameters:

◆Application range:

1. Separate fine suspended solids and algae in surface water.

2. Recycling useful substances in industrial wastewater, such as pulp in papermaking wastewater.

3. It replaces the secondary sedimentation tank to separate and concentrate suspended matter such as sludge in water.