Product center

◆Equipment introduction:

The equipment has the characteristics of simple structure, automatic control in operation, large processing flow, few backflushing times, high filtration efficiency, low resistance, and convenient operation and maintenance. It is an earlier and more common type of advanced sewage treatment in the field of environmental protection. Quartz sand filtration is an effective means to remove suspended solids in water. It is an important unit in advanced sewage treatment, sewage reuse and water supply treatment. Its function is to further remove the flocculated pollutants in the water. It passes through the interception, sedimentation and Adsorption, to achieve the purpose of water.

◆Advantages of activated carbon filter:

1. Low one-time investment: There is no need to set up coagulation tanks, clarification tanks and other facilities, no backwash pumps, electric and pneumatic valves and other equipment, the amount of engineering is small, and one-time investment is low.

2. Small footprint and beautiful appearance: It integrates the traditional three-stage reclaimed water treatment process, saving about 70 to 80% of the land, and the appearance is more beautiful and compact.

3. Loose inlet water quality requirements: it can withstand the 150mg/L concentration SS inlet water quality for a long time, and withstand the 300mg/L concentration SS impact for a short time without changing the outlet water quality.

4. Stable effluent water quality and good filtering effect: The filter material is clean and timely, which can ensure high-quality and stable effluent effect without periodic water quality fluctuations.

5. Easy to rebuild and expand: The adopted unit operation mode can flexibly increase or delete the number of filters according to the change of water volume, which is easy to rebuild and expand.

6. Low maintenance cost: There are no rotating parts except the activated carbon filter material during operation, the failure rate is low, and the maintenance cost is low.

7. Small head loss: single filter material and the filter material is clean and timely, the head loss is small, and the total head loss is ≤0.5m.

8. Low operating cost: no need for high-lift and large-flow backwash pumps.

9. High efficiency: 24 hours of continuous work, no need to stop and backwash.

◆Principle of activated carbon filter::

After high temperature carbonization and activation, activated carbon has stable chemical properties, can withstand strong acids or alkalis, can withstand the effects of water immersion, high temperature, and high pressure, and is not easy to crush.

If the pore size of activated carbon is mainly micropores, then it will be used to carry out gas or liquid phase heavy molecular weight, small molecular diameter substances have a good effect. If the mesopores and micropores of activated carbon are more developed, then activated carbon is suitable for adsorbing substances with larger molecular weight and diameter in the liquid phase.

In water treatment, the molecular diameter of the adsorbate is much larger than the molecular diameter of the adsorbate in the gas phase adsorption. Therefore, the activated carbon used for water treatment requires a proper ratio of macropores and mesopores and has Well-developed micropores.

In the specific sewage treatment, the larger the specific surface area of the activated carbon and the more developed the pore size, the better the effect of sewage decolorization, deodorization and COD reduction. Therefore, in the water treatment, choosing to use about 300 mesh activated carbon can save more on the amount.

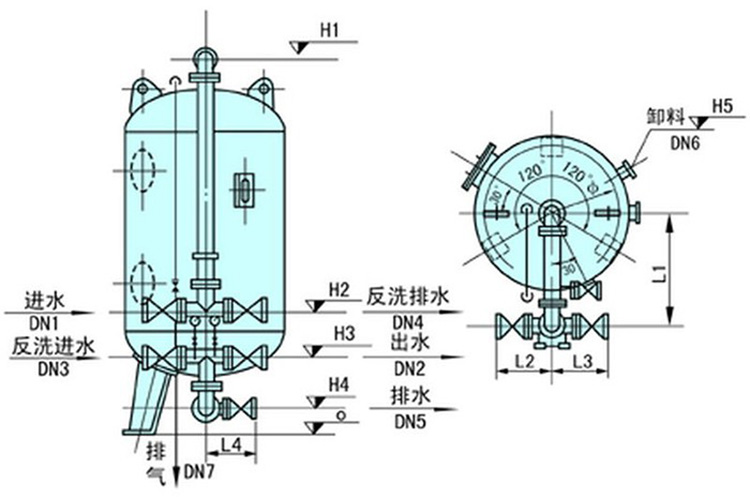

◆Device parameters:

◆Application range of activated carbon filter:

It is widely used in food, medicine, electronics, chemical industry, industrial wastewater and other industries.

1. It can meet the requirements of the hydraulic system for filtration accuracy, and can prevent certain impurities from entering the system;

2. The filter element should have sufficient strength and not be damaged due to pressure;

3. Large flow capacity and small pressure loss;

4. Easy to clean and replace. Installation points: