Product center

◆Product description:

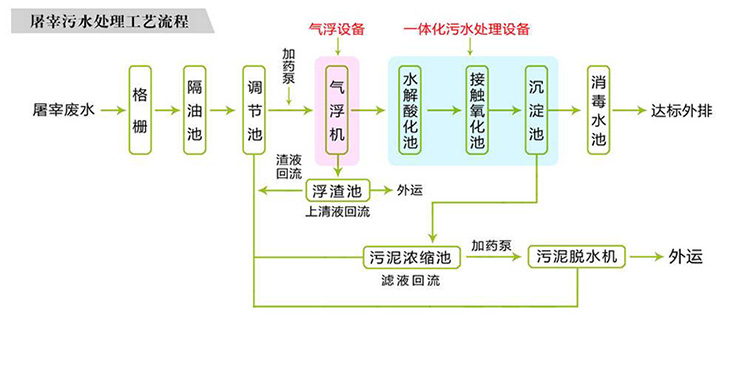

The slaughter sewage mainly comes from the sewage produced by the processes of fence washing, leaching, slaughter and factory floor washing, scalding, dissection, non-staple food processing, and oil washing. Slaughter sewage has high organic matter content, high suspended matter content, and a certain amount of grease, blood stains, etc., and has good biochemical properties. According to the characteristics and difficulties of slaughter wastewater, our company mainly adopts the process of grille + oil separation adjustment + air flotation + hydrolysis acidification + contact oxidation + precipitation + disinfection to design slaughter wastewater treatment equipment.

◆Process description:

(1) Grille

Slaughter sewage flows through two thick and thin grids successively to remove large suspended matter and floating matter to prevent the sewage lifting pump and other mechanical equipment from being blocked.

(2) Grease trap adjustment tank

The sewage treated by the grille flows into the oil-separating adjustment tank, and the oil floats on the water surface and can be manually removed for recycling. Due to the large fluctuations in the quality and quantity of sewage, to ensure the subsequent treatment effect and operational stability, an adjustment tank is set in the treatment process to homogenize the water quality and quantity and ensure the smooth operation of the system.

(3) Air flotation machine

Blood stains, grease, oil lumps, etc. contained in sewage can be effectively removed by coagulation and air flotation.

(4) Hydrolysis acidification tank

Because the organic concentration of this kind of sewage is not very high, according to the company's experience in the treatment of low-concentration organic sewage, anaerobic digestion treatment can be used instead of the hydrolytic acidification process. The bacteria that play a role in the hydrolytic acidification process are hydrolytic bacteria and acid-producing bacteria. They are all under anaerobic conditions and do not require dynamic aeration. Therefore, the hydrolytic acidification tank can partially degrade organic matter without energy consumption, reducing operating costs; At the same time, the acid hydrolyzing bacteria can convert the difficult-to-degradable organic matter of the large molecule into the organic matter of the small molecule that is easily degradable, thereby improving the treatment effect of the subsequent aerobic treatment unit. The use of the hydrolysis acidification process can greatly shorten the time required for aerobic biochemistry; at the same time, the quality of the effluent after treatment is better, which not only saves investment, saves operating costs, and improves environmental benefits.

(5) Aerobic contact oxidation tank

Biochemical treatment is mainly through aerobic treatment. When sufficient dissolved oxygen is provided in the sewage, most of the organic matter in the sewage is removed by the adsorption and degradation of aerobic microorganisms.

(6) Sedimentation tank

The sedimentation tank uses sedimentation to remove suspended solids in water. The removal of SS in sewage mainly depends on sedimentation. The sedimentation tank consists of five parts: water inlet area, water outlet area, sedimentation area, mud storage area and buffer zone. The function of the water inlet area and the water outlet area is to keep the water flow in and out uniformly and smoothly to improve the precipitation efficiency. The sedimentation area is the main part of the tank. The sludge storage area is the place where the sludge is stored, which plays the role of storage, concentration and discharge. The buffer zone is located between the sedimentation zone and the sludge storage zone. The function of the buffer zone is to prevent the sludge sinking at the bottom of the pool from being carried away by the water flow.

(7) Disinfection pool

The equipment adopts chlorine dioxide disinfection method. The disinfection ability of chlorine dioxide is much higher than that of other chlorine series disinfection products. The disinfection pool and disinfection device are configured or not configured according to the needs of the project user.

◆Equipment advantages

1. The biological contact oxidation treatment process used in the equipment is smaller than the activated sludge tank, has strong adaptability to water quality, good impact load resistance, stable effluent quality, and no sludge expansion.

2. The filler has a large specific surface area, and the microorganisms are easy to be filmed and removed. Under the same organic load condition, the removal rate of organic matter is high, stable and reliable, and at the same time, there is no need to add chemicals, which saves subsequent costs and reduces operating costs.

3. Hydrolysis acidification can effectively discolor the sewage, decompose macromolecular organic matter, reduce the subsequent processing load and save investment.

4. Ideal precipitation effect and better effluent quality can be obtained.

5. Adopt a special structure to reduce the spread of odor.

6. The equipment is made of carbon steel anti-corrosion treatment or stainless steel components, spliced and assembled on site, light in weight, easy to transport and easy to install.

7. It adopts glass fiber reinforced plastic, carbon steel, stainless steel anticorrosive structure, has excellent characteristics such as corrosion resistance and anti-aging, and has a service life of more than 15 years.

8. The equipment can be placed below the ground surface, and the ground surface above the equipment can be used for greening or other land, without the need for building, heating, and insulation. Realize the integration of the system and reduce the footprint. If the equipment is placed on the ground, take care to keep it warm.

9. It can treat sewage from the slaughter industry and similar industrial organic sewage.