Product center

◆Overview:

Farming sewage has the typical "three highs" characteristics, that is, high organic matter concentration, COD as high as 3000-12000mg/L, ammonia nitrogen as high as 800-2200mg/L, suspended solids SS exceeding the standard dozens of times; normal biodegradability; strong odor; flushing discharge The time is concentrated and the impact load is large. According to the characteristics of the sewage, the treatment method of physicochemical + biochemical method can achieve a good treatment effect.

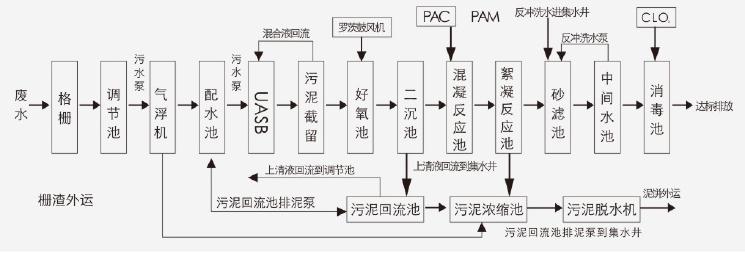

◆Process

The aquaculture sewage is removed by the grille and solid-liquid separator to remove most of the bulky debris, and then enters the regulating tank. In the adjustment tank, due to the large fluctuations in the quality and quantity of sewage, to ensure the subsequent treatment effect and operational stability, an adjustment tank is set in the treatment process to homogenize the water quality and quantity and ensure the smooth operation of the system. After the aquaculture wastewater passes through the regulating tank, it is sent to the up-flow anaerobic sludge reaction bed form (UASB anaerobic tower) by the lifting pump. The organic matter is hydrolyzed under anaerobic conditions, and the biodegradable high molecular organic matter is transformed into the biodegradable small molecular organic matter for subsequent processing. The wastewater is further hydrolyzed from the UASB anaerobic tower effluent hydrolysis acidification tank, and further transformed from biodegradable high molecular organic matter into biodegradable small molecular organic matter. Then enter the contact oxidation tank for aerobic treatment. When sufficient dissolved oxygen is provided in the sewage, most of the organic matter in the sewage is removed by the adsorption and degradation of aerobic microorganisms. At the same time, the mixed liquid returned from the contact oxidation tank is denitrified under the action of the denitrifying bacteria to achieve the purpose of biological denitrification. The anaerobic reaction sewage enters the hydrolysis acidification tank and the contact oxidation tank again to further degrade organic matter and remove a large amount of phosphorus. Then enter the sedimentation tank for mud-water separation, and the supernatant will be discharged up to the standard.

◆Application range of aquaculture sewage treatment equipment

It is suitable for the sewage produced by various farms (duck farms, chicken farms, pig farms, cattle farms, etc.).

◆Advantages of aquaculture sewage treatment equipment

1. The aquaculture sewage treatment equipment developed and produced by our company is made of carbon steel anti-corrosion treatment or stainless steel components, spliced on site, lightweight, easy to transport, and easy to install;

2. It adopts glass fiber reinforced plastic, carbon steel, stainless steel anticorrosive structure, has excellent characteristics such as corrosion resistance and anti-aging, and has a service life of more than 15 years;

3. No peculiar smell, reducing secondary pollution;

4. Not limited by the amount of sewage, it is flexible and can be used individually or in combination.